1⁄72Douglas C-117

3

Comments

History

At the end of WWII, all aircraft manufacturers were stimulated to intense civil activity in an attempt to produce the most efficient and economical aircraft in a given class, a task, which was not so easy as it first sounded. A legend soon sprang up that the only replacement for a DC-3/C-47 was another DC-3, and surprisingly though many tried to produce a better design than the then 12 year old DC-3 it was going to be many years before such a situation did come about.Such was the long life of the DC-3 airframe that Douglas eventually came up with an idea to update the DC-3 with increased capacity and payload by re-engineering the old airframe and bringing the various systems up to date. By the time various airframe modifications to effect these changes had been carried out a very handsome Super DC-3 resulted.

The airlines were unimpressed. Though seeking interim equipment before the arrival of the jets they found the cost of converting a war surplus C-47 almost as much as buying a new twin-engine, tricycle-undercarriage, Convair 240, and thus the DC-3s idea almost died.

The USAF was equally unimpressed and took the airlines view that the Convair C-131 was much to be preferred, so it was left to the USN and USMC to eventually decide that a large proportion of their weary R4D-5 fleet could be usefully revived by receiving the DC-3s treatment, and a hundred or so machines were phased through Douglas, to emerge as R4D-8s. During the revision of July 1962 when all service airframe designations were rationalised, the R4D-8 became known as the C-117. The conversion to C-117 standards consisted by the installation of more powerful engines, the fitting of new wings, a new tail unit, lengthened fuselage ahead of the wing and modification of the undercarriage. The result of this conversion is virtually a new aeroplane, but proposals for similar commercial conversions did not meet with success.

The new medium-range military transport was powered by two 1,535 h.p. Wright R-1820-80 radials giving a maximum speed 270mph at 5,900 ft; and cruising 251mph at 15,400 ft. The C-117 had a wingspan of 90ft and a length of 67ft 8.5 in.

Between 1964 and 1969 I have recorded over 8 different US Navy C-117Ds landing at Hal-Luqa airfield, Malta. The type was remarkably faster than the DC-3, and a lot noisier with the more powerful engines. The ones that used to call had the Naval Air Facility title indicated on their fin and rudder, normally Sigonella or Naples. Some carried the grey and white colours, others had silver and white top with day-glow areas on wing tips, front and aft fuselage. They were the Navy workhorses of the day until eventually were replaced by the C-130.

Typical C-117Ds spotted here were 12439 on 12.9.66 ex-C-47A 42-23810, 17102 on 31.8.66 ex-C-47A 42-108804, and 17116 (Naples) 25.9.66 ex C-47A 42-108818 ex USMC.

The kit

This is a 1/72 scale vac form model in white Styrene issued by Airmodel of Germany, somewhat basic but a good basic model to build a C-117, containing all the different parts which when merged with other DC-3 items makes a very satisfactory model. The parts that should be added consist of a pair of propellers, undercarriage assembly, wing central section and possibly the port cargo doors. All parts are otherwise there to complete the model of the C-117D. This of course requires a certain amount of detail work as well as correction of some of the parts. Good scale plans are provided. These not only show side and plan view elevations but also detail scrap views of the interior so that the cargo compartment with basic seating arrangement as well as cockpit office is provided. Drawings include those for rear and aft bulkheads as well as cargo deck, all of which are cut and shaped from backing sheet of plastic that come with the kit.Construction

The kit was released over 25 years ago and was the first of the type to appear in 1/72 scale. A welcome addition at the time however certain parts need to be improved to make a good representation and these include the cowling area, tail end, and shape of fin and rudder and nose area. Whereas the panel lines appear well represented particularly those on wing surfaces these needed refresh scoring.Construction starts by marking around the edges with a soft pencil before scoring with a sharp pointed blade and gently snapping them away from the backing sheet. This is followed by wet and dry sanding on an abrasive sheet taped to a flat surface. It is much easier than using a sanding block, as it is a fairly large kit. In doing so it allows more control of pressure, which is evenly spread on the whole surface of parts. After preparing the two fuselage, two wing halves, two tail plane halves and engine cowling pieces these are sanded and care is taken not to reduce these excessively due to the soft plastic. Engine cowlings are checked with drawings and a mild defect is corrected with a small amount of filler and shaping with needle files. The Airfix radial engines are carefully inserted inside the cowling (as these show the engine cylinder detail), which is now assembled to form a complete cowling less wheel well doors that were carefully cut and left to a later stage. The doors were further detailed by adding an inner surface with cut round areas, see photo. The lower air intake is somewhat crudely represented but with care and reference to drawing provided and photos will have the intake cut open and a gauze added inside. The outer sides of the cowlings are further shaped with needle files, a deflector plate added to each side and also a long exhaust pipe made from sprue is added. This had the outlet drilled open.

The interior compartments are now built up from the extra plastic that comes with the kit. Using tracing paper these were drawn on the flat sheet sections and cut, built up and seats added where appropriate. Fuselage is also cut, sanded brought to correct width and all rectangular portholes cut and shaped accordingly. An extra smaller window is also added to the starboard forward fuselage and two small portholes are drilled at forward fuselage. Intermittent plastic stabs are added on the inside to join the fuselage halves together once the interior is assembled and painted. The central wing section from an old Airfix kit was prepared so that it securely fits the centre of fuselage. Wing sections are sanded from both the inside and also the outside otherwise they will show being on the thick side. Careful scraping along the length of the wings brought the required airfoil section thickness. A slot was cut to insert a piece of clear plastic to form the leading edge light to port wing. Tail planes were also corrected at the rear root area. Fairing with Revell Plasto filler was essential. Panel lines were redrawn and tail planes were inserted inside a slot cut at the rear fuselage. Cockpit area was prepared to receive the clear acetate canopy. A cardboard jig was drawn, cut and assembled so that when the wings are joined to the fuselage they rest on this jig and have the correct dihedral while they are setting. A tail wheel was added from spares. This had the leg built up from plastic card as it differed from the C-47 wheel that comes in the Airfix kit. The main wheels also had a 1mm insert added at the centre to broaden their track. Detail also added to the oleo legs as per drawing.

Colour and decals

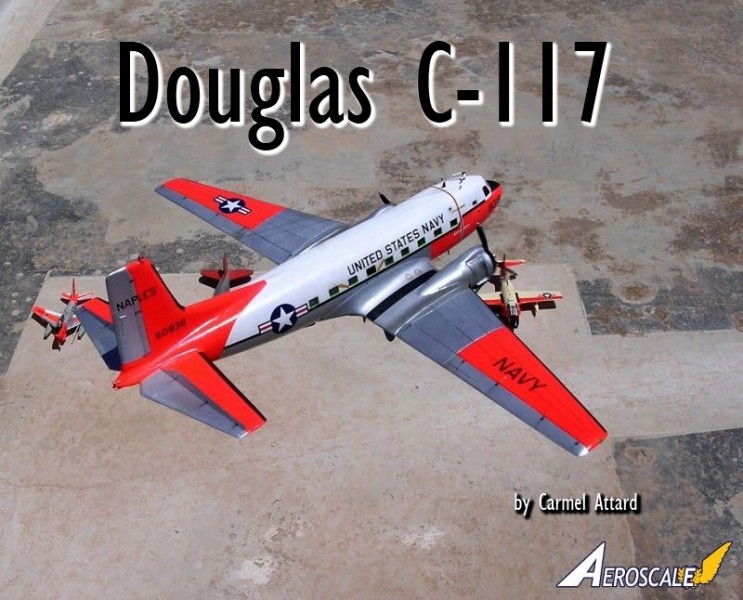

The kit took exactly 4 weeks to complete. The C-117 in Naval and Marines service carried a variety of liveries. The first rebuilt aircraft were phased into operation during the latter part of 1951, and the work proceeded steadily over the next two years. The early machines were finished only in anodised metal, but soon an overall finish of light grey became standard.By the mid 50s a smarter paint scheme existed, having a white top to the cabin and upper surfaces, but still with light grey to rest of the aircraft. Some retained the silver fuselage and wings, particularly the ones that came during the Day-glow orange colours era. Cockpit interior was dark grey and greys and blue greys were used on some in the passenger cabin area while earlier had chrome green finish., depending on the role in use. Interior of wheel wells and other areas were in chrome yellow and some in silver finish. Undercarriage parts were originally in plated metal finish, but later these were painted, much according to the preference of the unit user. Several were finished in white. Paint scheme and markings varied greatly during service life so individual details were carefully studied. Black non-slip walkways were provided on the upper centre-section skins. A black decal film was used for walkways. The leading edge de-icing boots were painted acrylic paint and matted at the end. I used Model Master day glow to various areas on the C-117. The national insignia placed on the upper and lower outer wing had a silver periphery. The star and bar insignia came from Italeri R4D kit N127. These were stuck on a silver decal sheet and allowing 1mm of silver at the periphery were cut with scissors. Due to additional windows on the starboard side, the national marking on this side was two feet further aft than that on the port side. Blue/black cheat line was cut from a solid colour decal sheet and Naples legend as well as the serial number came from decal spares box. Perhaps this is one drawback with early Airmodel kits. They lacked even the one decal set and if this policy is changed maybe it will have a positive effect on these types of kits.

Conclusion

Building a vac form kit is just the style of adding an unusual type without going to the sky-high cost of getting the same equivalent in resin. I thoroughly enjoyed building the C-117D as with little effort it turned into an accurate replica as well as a challenging experience to finish. The type brought many happy memories of a common type that used to land at both Hal-Far and Hal-Luqa through the 60s.Carmel J.Attard

Comments

Hi there

What a stunner! If ever there was an advert for trying some classic vacuforms, this is it!

Hmmm... he says wistfully, eyeing his Stash....

All the best

Rowan

DEC 21, 2013 - 09:43 AM

Hi again

I'm surprised no-one else has commented on just how convincing some of the "in flight" photos are. We're seldom blessed with full-on sunlight like that here in the UK - and the usual advice for model photography is to aim for soft, diffused lighting - but there's something about the crisp natural light that really makes the model look full-sized. Some of the thumbnails had me thinking you'd been to an airshow!

All the best

Rowan

DEC 27, 2013 - 08:57 AM

How'd he do that?? Looks like someone tossed the thing in the air and he snapped it mid fall!

DEC 27, 2013 - 10:07 AM

Copyright ©2021 by Carmel John Attard. Images also by copyright holder unless otherwise noted. The views and opinions expressed herein are solely the views and opinions of the authors and/or contributors to this Web site and do not necessarily represent the views and/or opinions of AeroScale, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of AeroScale. All rights reserved. Originally published on: 2013-12-21 07:00:16. Unique Reads: 5348