Progress at last!

I finally managed to get everything in the main fuselage ready for assembly. The complexity means I had to paint everything before assembly, which of course makes glue fun to use. Clamps, a little bit of kabuki tape, and some Tamiya Extra Thin did the trick though.

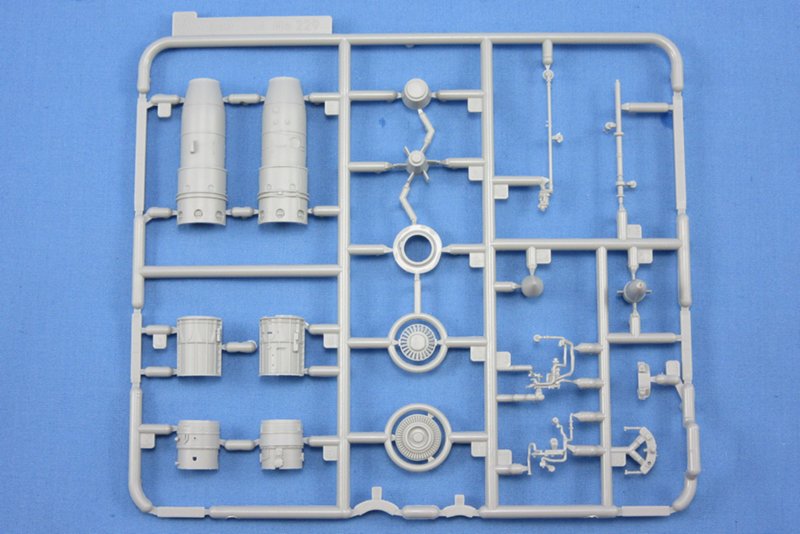

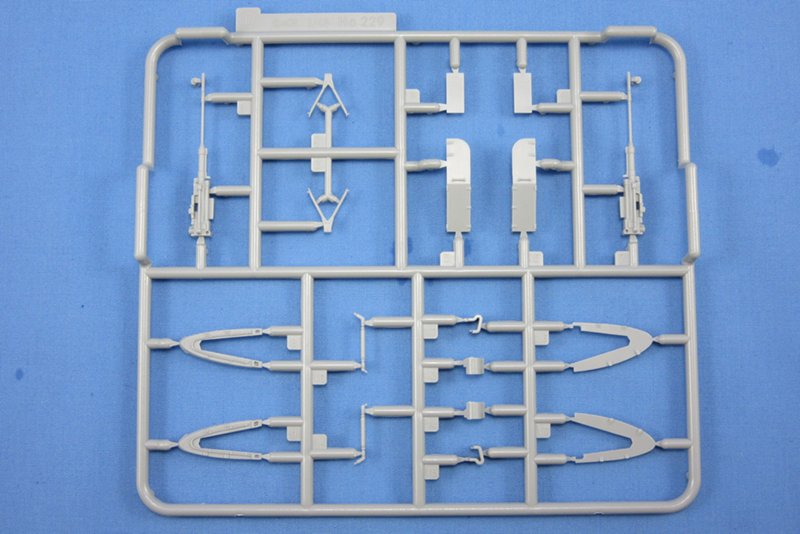

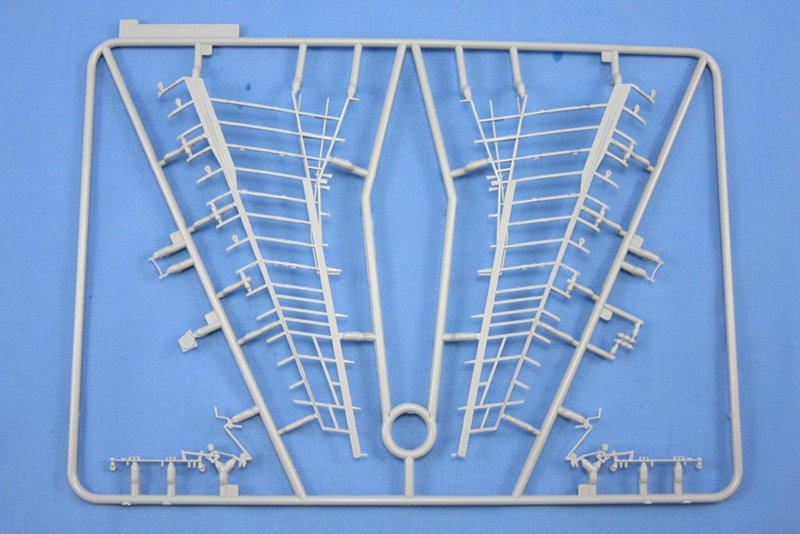

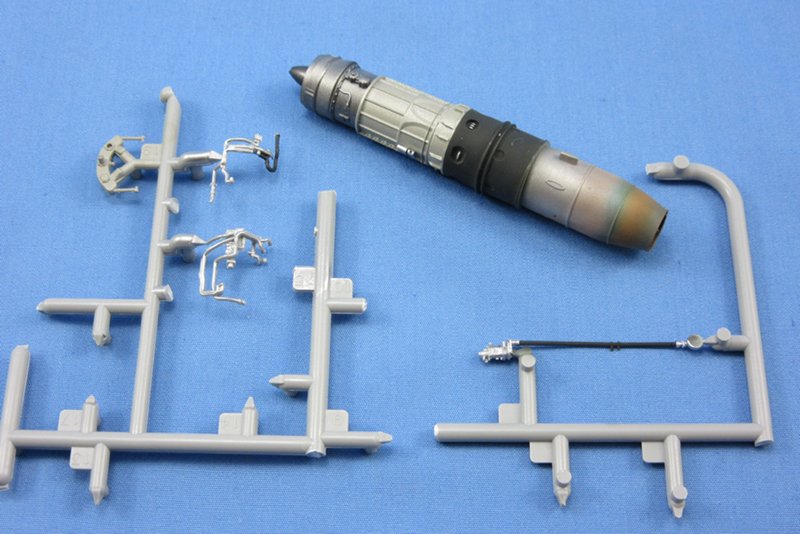

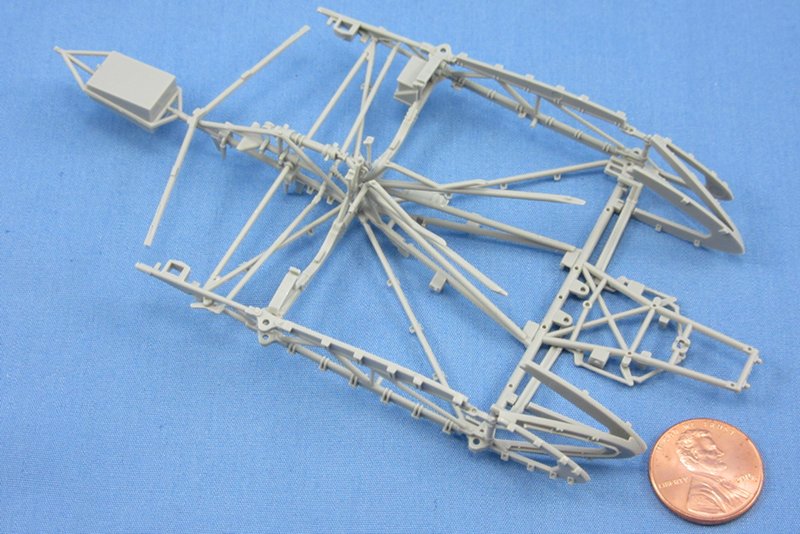

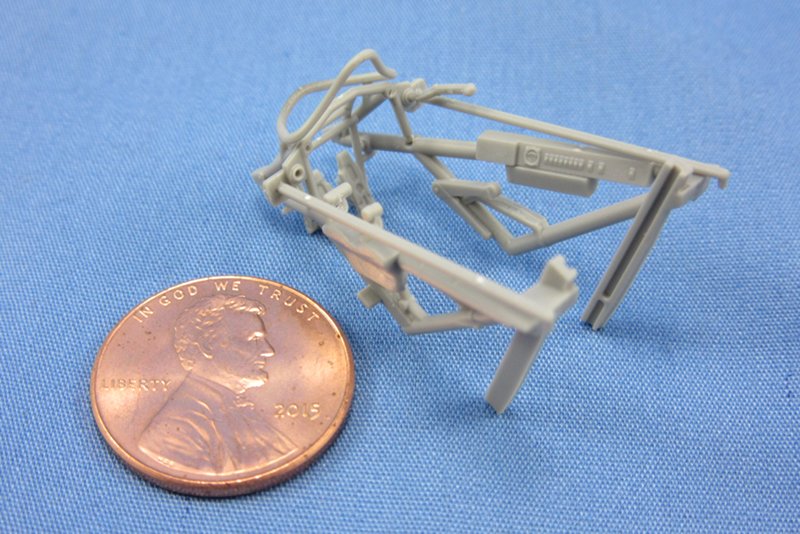

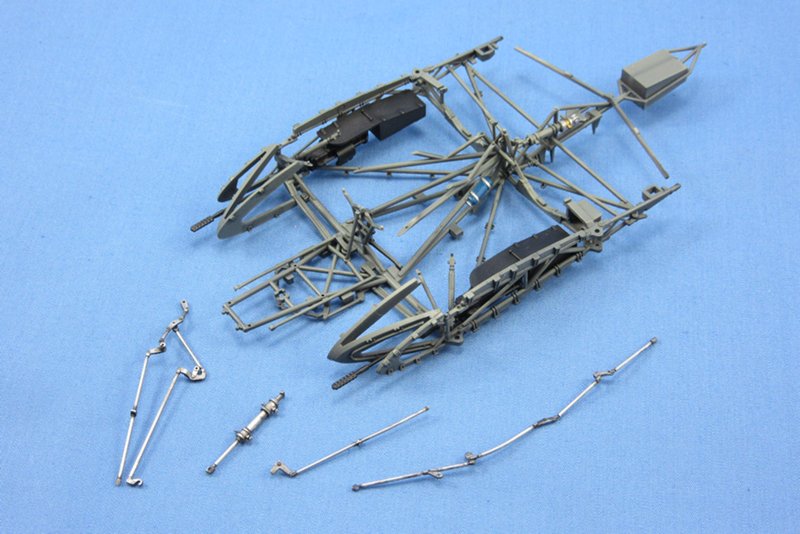

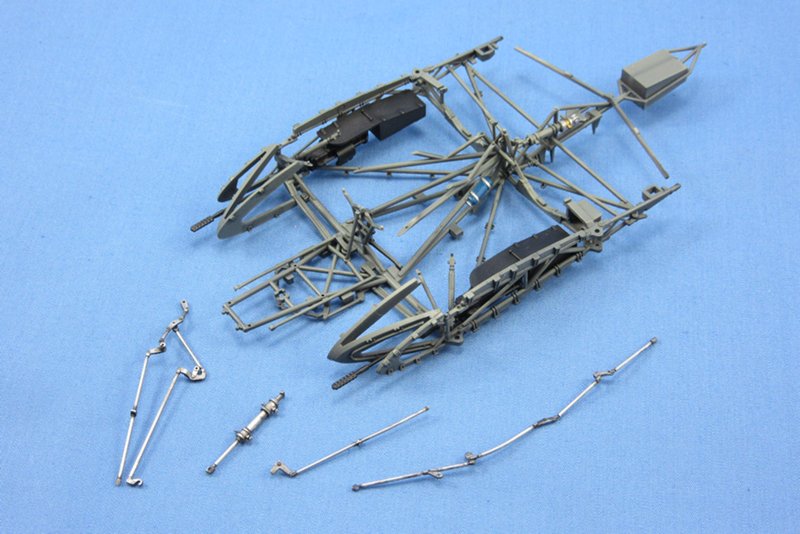

First up were these linkage rods.

First up were these linkage rods.The linkage have to be threaded through the fuselage piping, but not glued until after the cannons and engines are mounted. Sounds fun right? Zoukei Mura include an addendum to the instructions with multiple views of everything to show you where the linkage need to go. Through here, under that, left of this, insert a pin here, under this, and finally on top of that. Then grab the next piece...

It actually wasn't that bad but lots of test fitting and careful planning are a must. The real problem is that these pipes all must sit at specific angles to attach to the frame properly, and the instructions really do not make the positions clear even with the addendum.

I

lightly glued the linkage in place once I managed to get them in their proper positions, and then waited until I had everything together to fix them permanently. It proved to be a delicate balance of just enough extra thin to hold them but not so much I couldn't break the weld and re-position it a bit to its final proper angle.

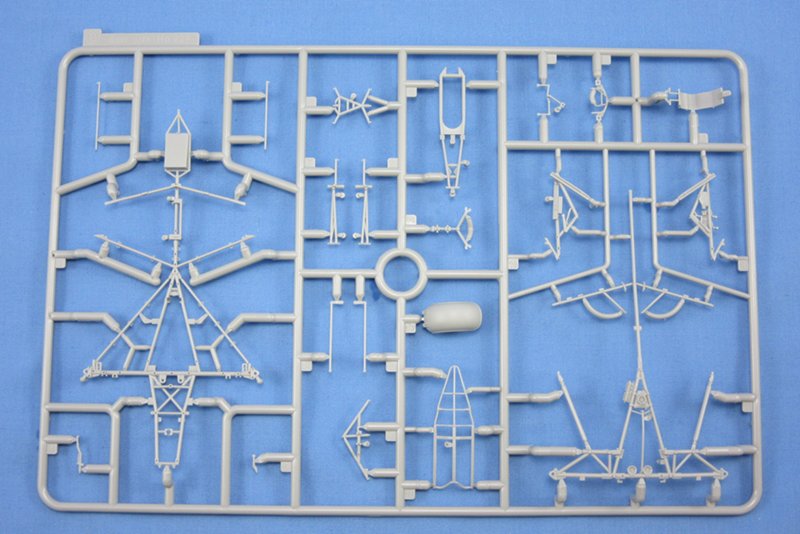

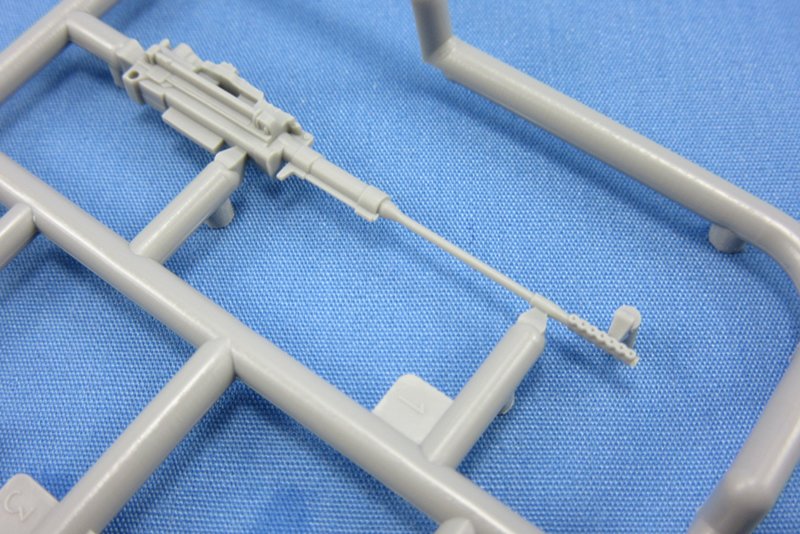

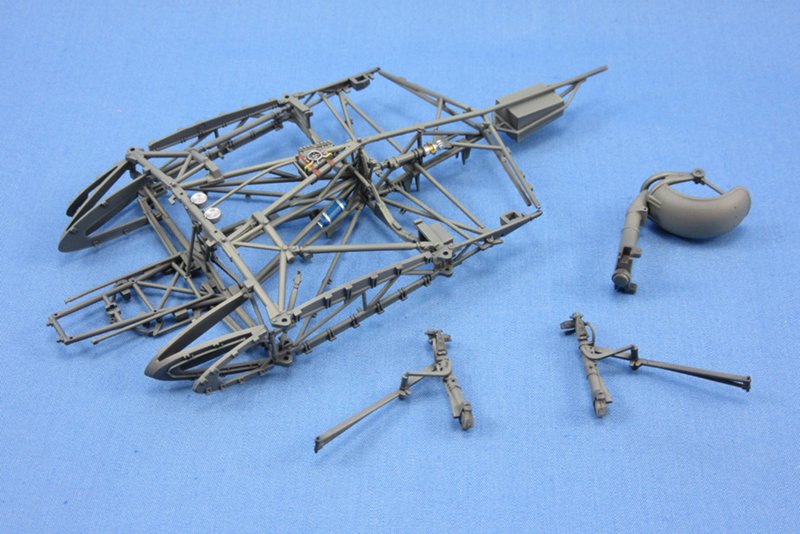

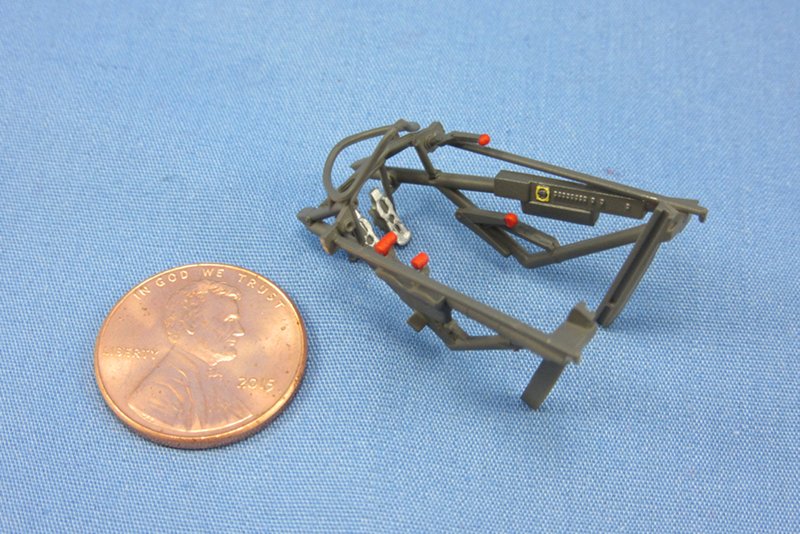

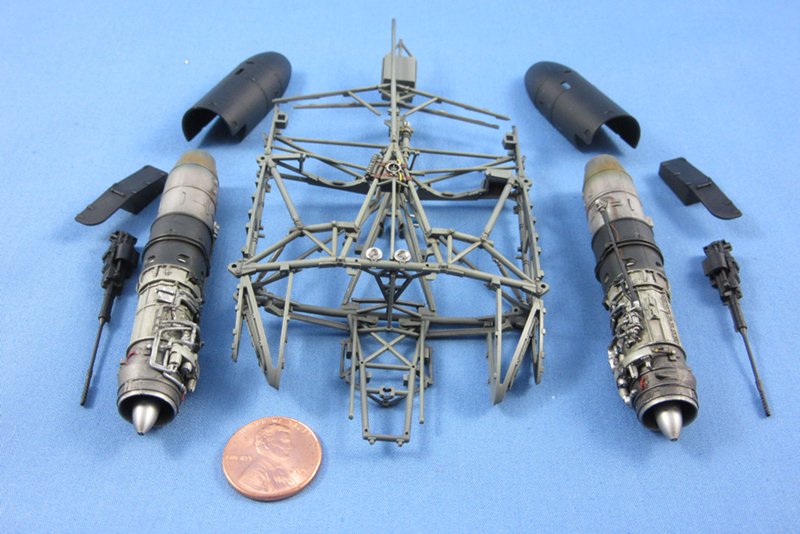

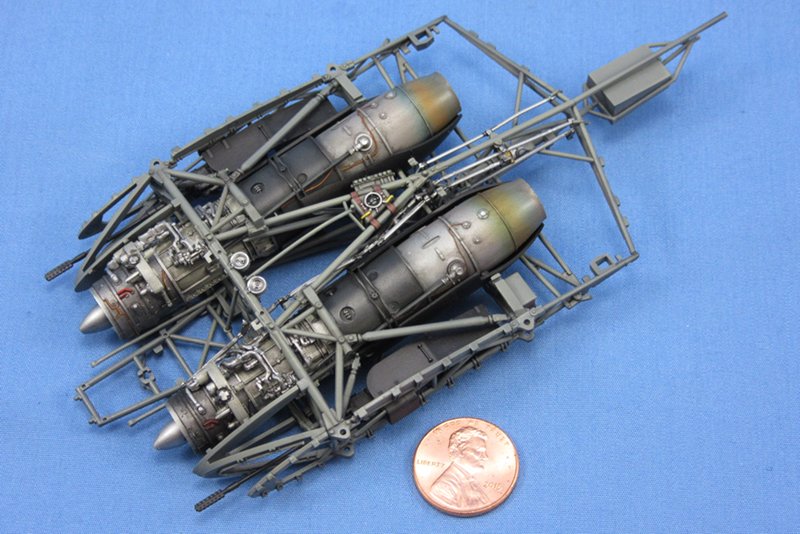

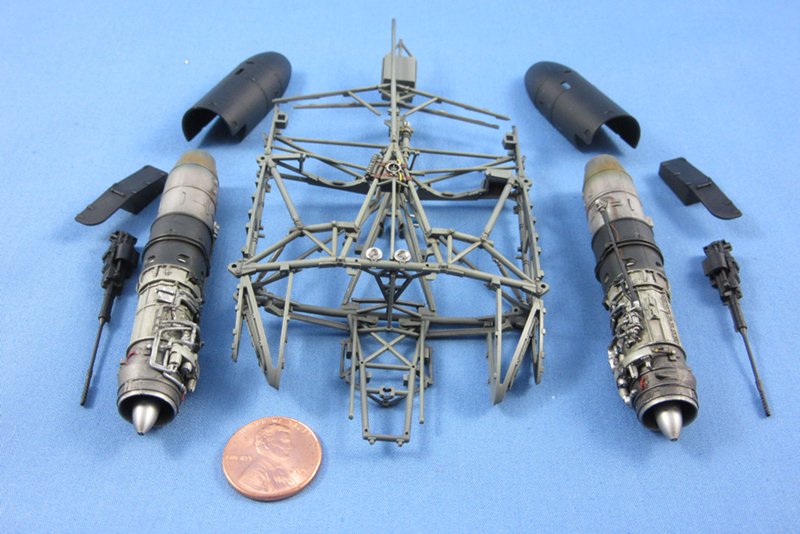

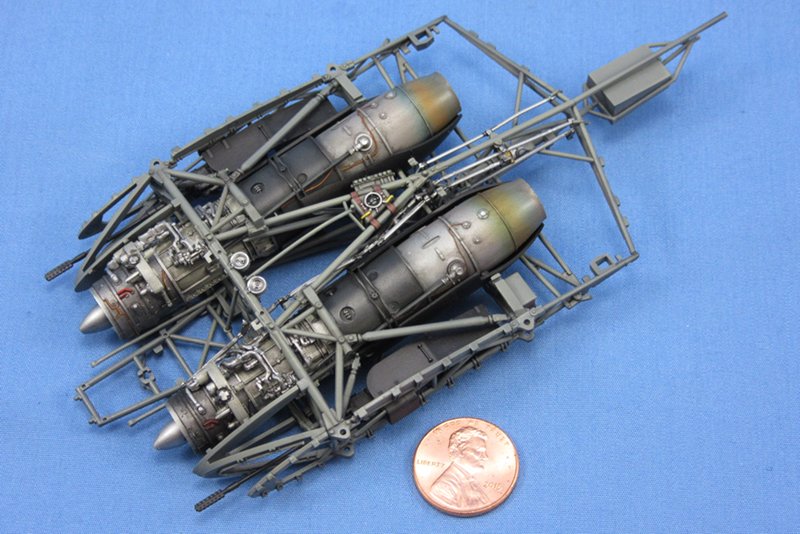

Next, all of this needs to go into there. It isn't obvious to look at but the piping is actually a bit of a rat's nest when you start sliding things inside the frame. The picture kind of makes it look open.

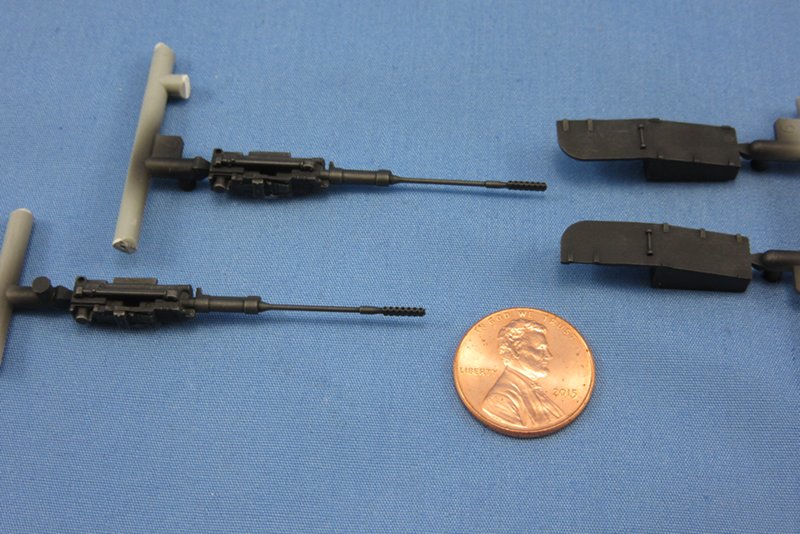

Next, all of this needs to go into there. It isn't obvious to look at but the piping is actually a bit of a rat's nest when you start sliding things inside the frame. The picture kind of makes it look open.The cannons went in first. They mount to a small peg and the barrels have to be threaded through the piping. A little patience when doing this pays off and they will slide in place easy enough. The peg is the only glue point for the cannons though, and aligning them properly is a bit tricky. I used the clear nose section to check everything during this assemble. I put one sub-assembly on, checked alignment with the nose piece, then moved on to the next. This kept everything on its proper axis. The ammo feed chutes glue in place after the cannons are mounted.

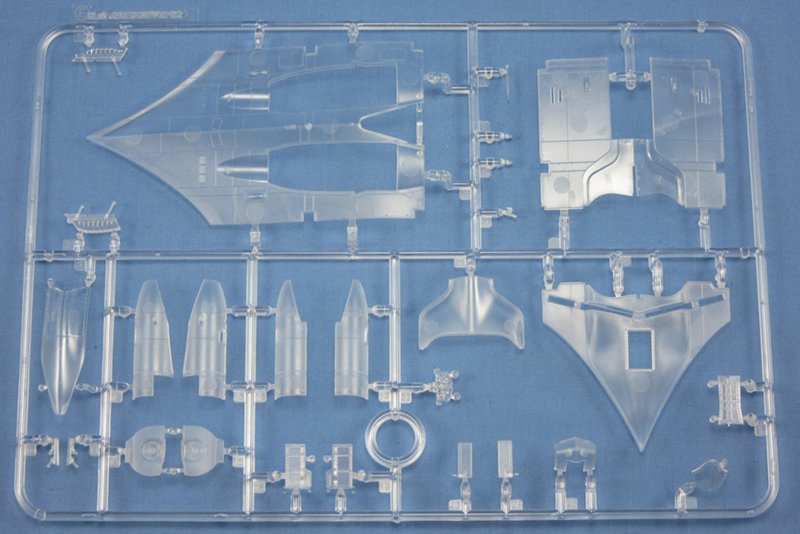

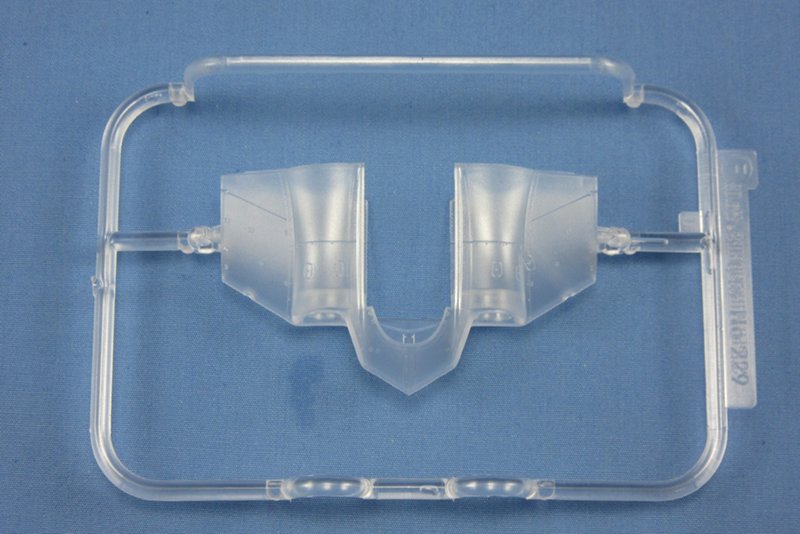

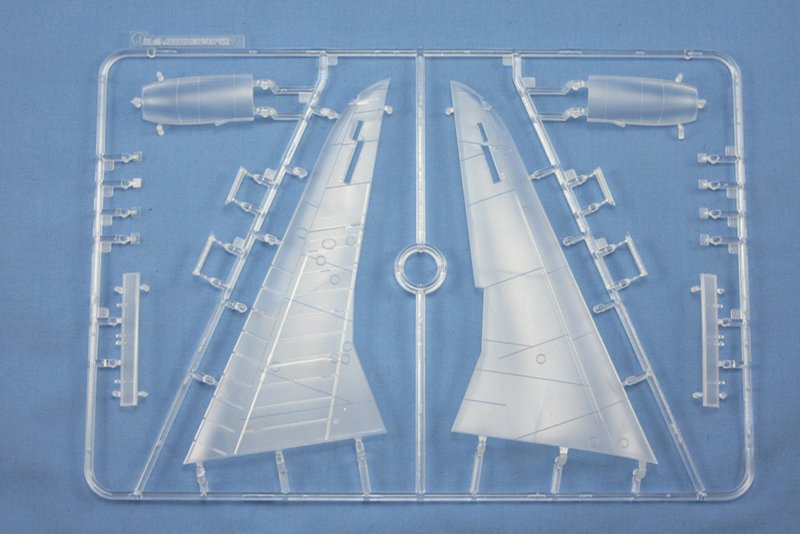

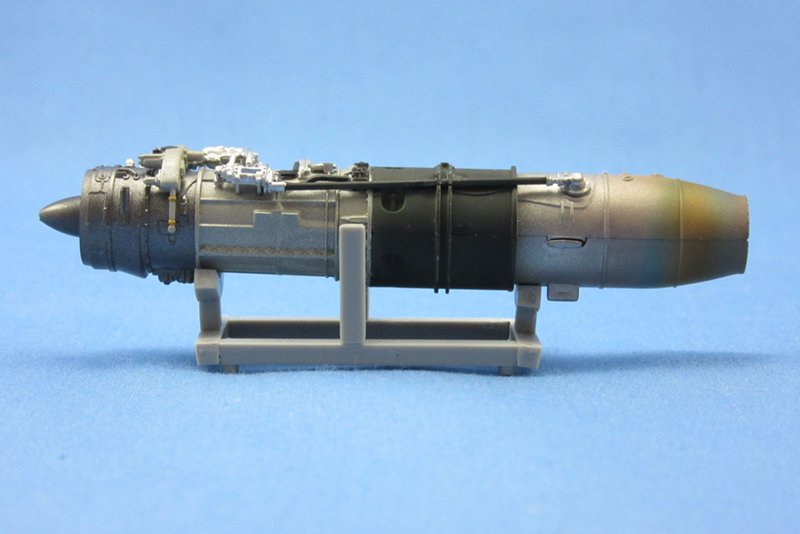

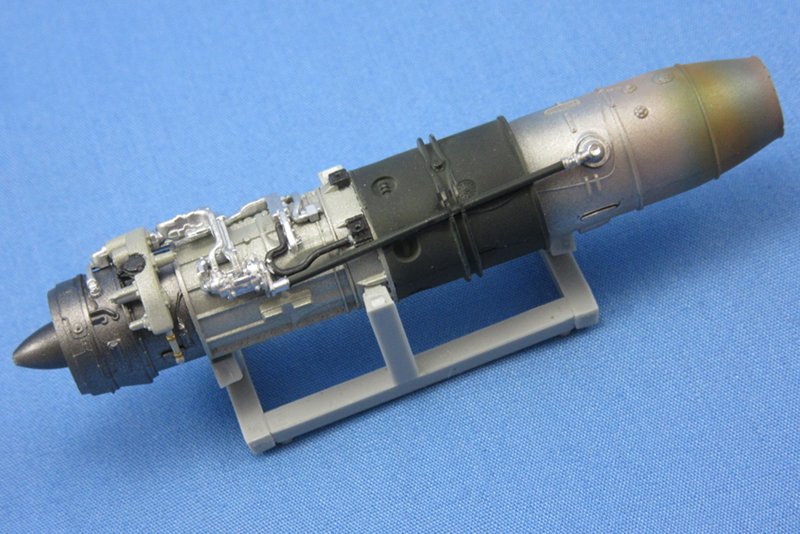

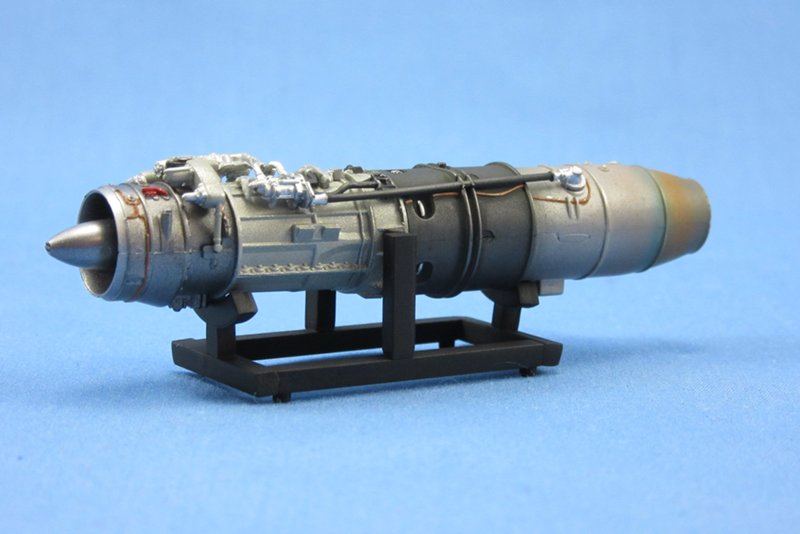

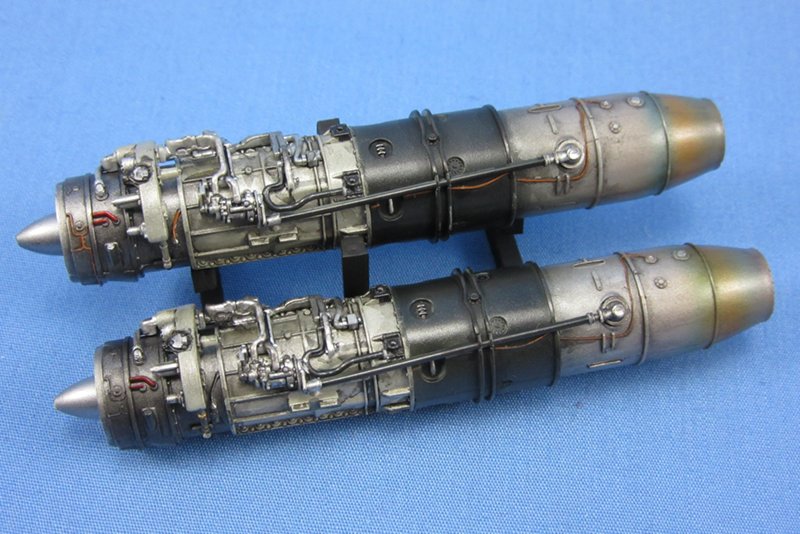

The engines were next and actually snap into place inside the heat shrouds if you spread the sides with just a little force. Not too much though, the shroud halves are actually clear plastic and a bit brittle. Once in place though, there is a solid tab and slot design which literally clicks into place. I didn't feel the need for any glue to hold them. Once that was done for both, I mounted them one at a time again checking each with the nose piece before doing anything else. The engines did not require glue either, they are a tight fit with very solid alignment pins and tabs to keep them straight. They will also literally click into position when you get them lined up correctly.

Once I had everything in place, it was time to add the top frame. This was a long and tedious process. To make sure the fuselage is properly assembled, you need to line up and glue the top frame to the lower assembly in

thirty-nine different spots! Zoukei Mura include a helpful isometric diagram and top view of this step that shows you every spot, but it is not a simple matter of popping it on and applying some glue all at once. Thirty nine individual connections just are not going to line themselves up perfectly without a bit of help.

I tackled this step by first drilling out all of the holes underneath the top frame to improve the connection points. This ensured that I wouldn't have to force the parts together due to a closed or narrow locating hole. Next I chose a central point to work from. There is a large locating pin close to the middle of the frame. I glued the top piece to the lower assembly here and clamped it tightly until the glue set. Once that was accomplished I started working my way outward, lining everything up and giving the plastic time to set before I moved on to the next point. There were plenty of small connections which needed to be coaxed into fitting properly, and pipes that had to have their positions adjusted or relocated. Doing it this way took me the better part of the afternoon today to add just this one piece, but it worked perfectly.

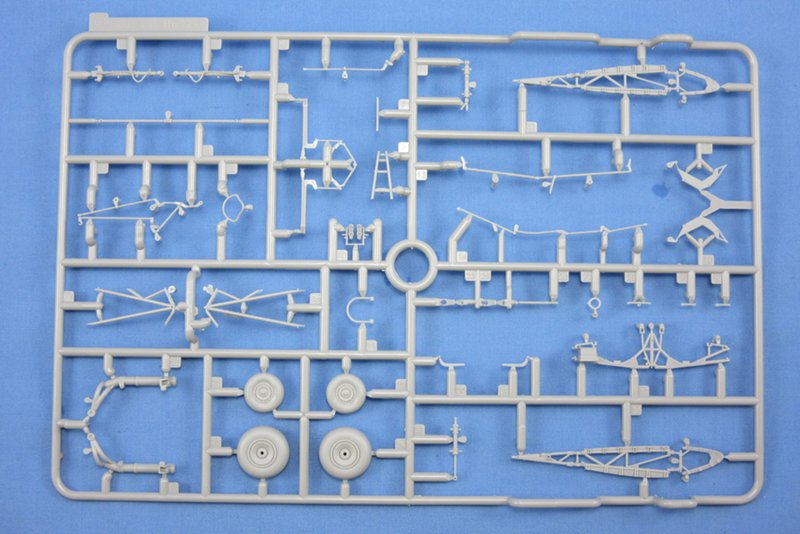

As I mentioned earlier in the build, the plastic is slightly soft and flexible, and this was a big advantage when trying to work through this step. I didn't have to fear breaking the tiny frames while trying to bend them a bit this way or that. In the end, everything worked out well and I have the main fuselage completed.

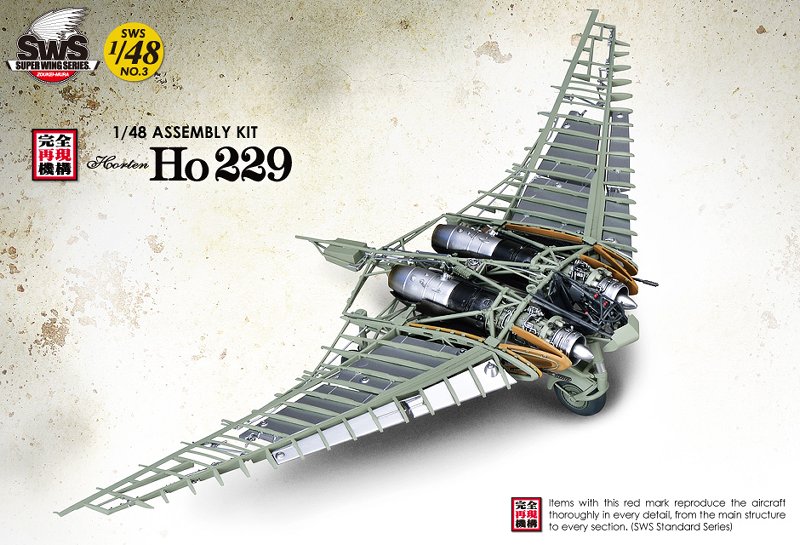

There are no less than 80 individual parts in this assembly. It is probably the most complex thing I have ever built out of plastic but in the end it worked out great. This is less a testament to my modeling skills than a nod to Zoukei Mura's marvelous engineering, with a little patience and forethought it goes together flawlessly.

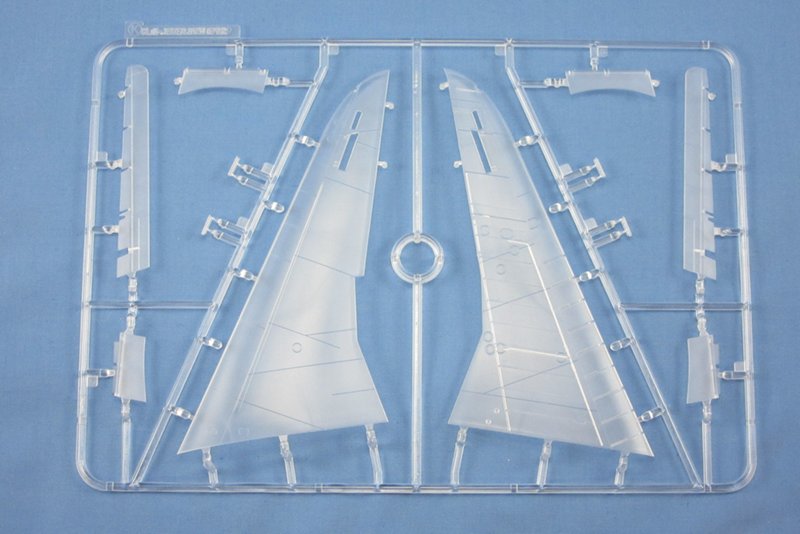

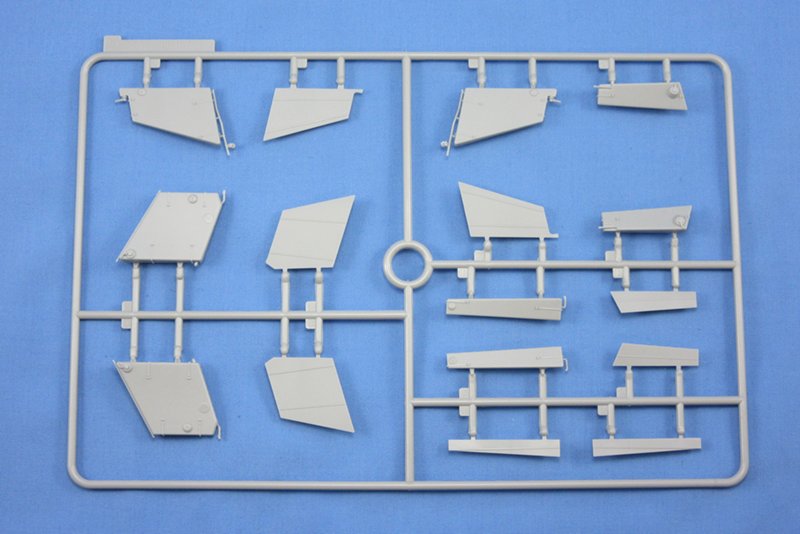

There are no less than 80 individual parts in this assembly. It is probably the most complex thing I have ever built out of plastic but in the end it worked out great. This is less a testament to my modeling skills than a nod to Zoukei Mura's marvelous engineering, with a little patience and forethought it goes together flawlessly.From here I need to finish the cockpit and add it, then do the same with the landing gear. Once that is out of the way the remaining construction should go quickly. The wings are much larger, more traditional structures to build. From here my main concern is going to be working with the clear skin sections. It is more brittle and less forgiving, but should be really interesting. This kit is definitely at the top of my list for favorite kit builds. I will obviously not complete it in time for the Hot Out Of The Molds II deadline, but I am not trying to rush and mess it up at this point.

More to come soon!