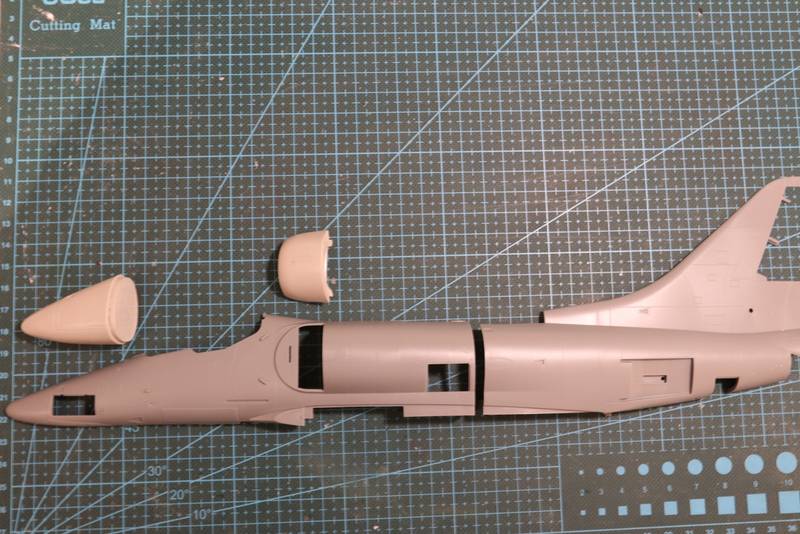

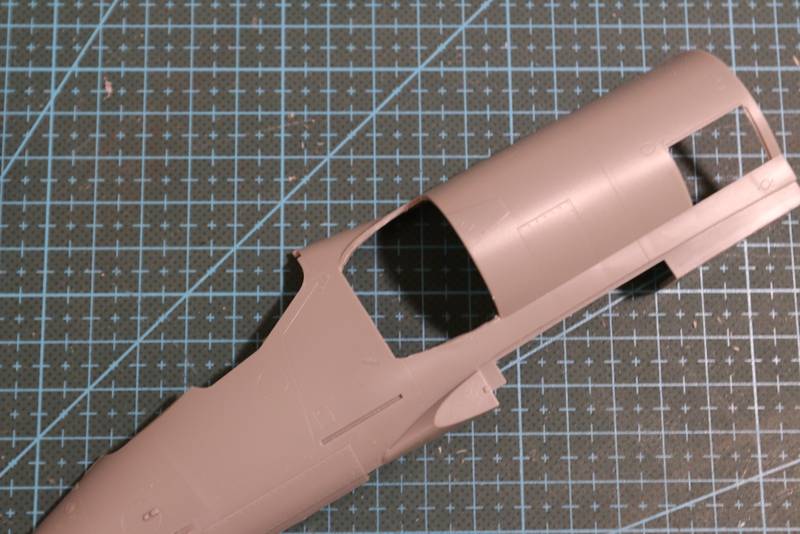

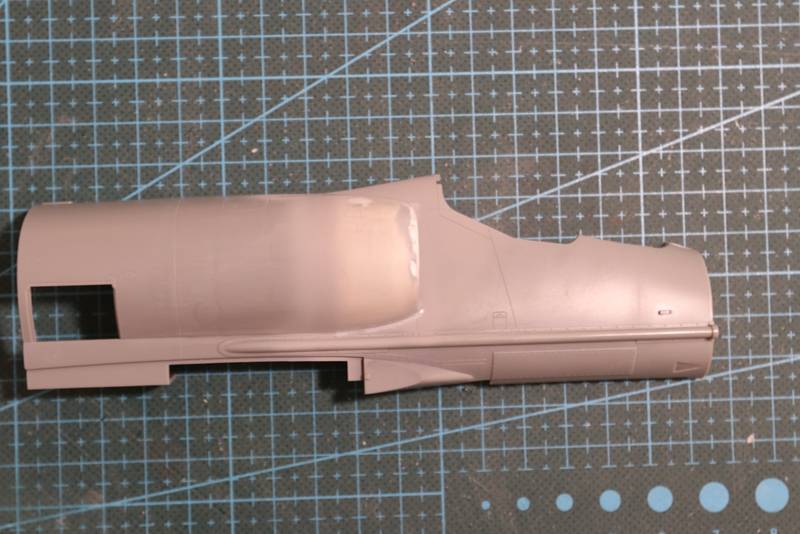

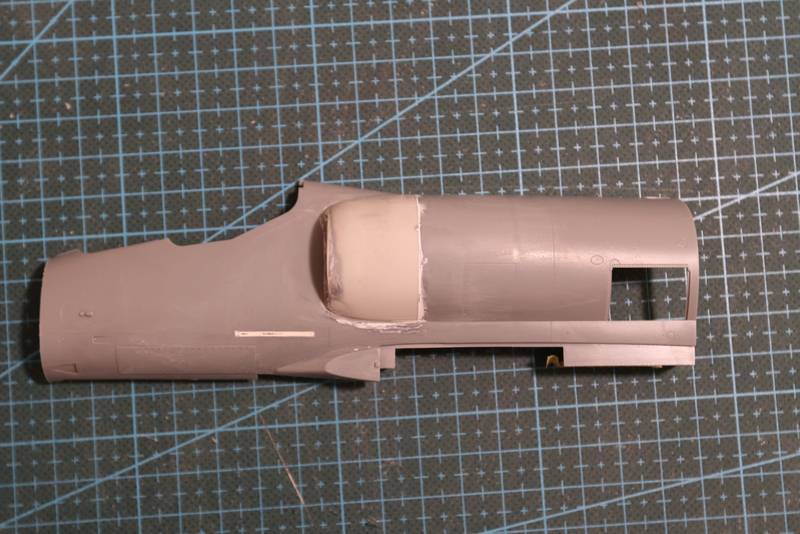

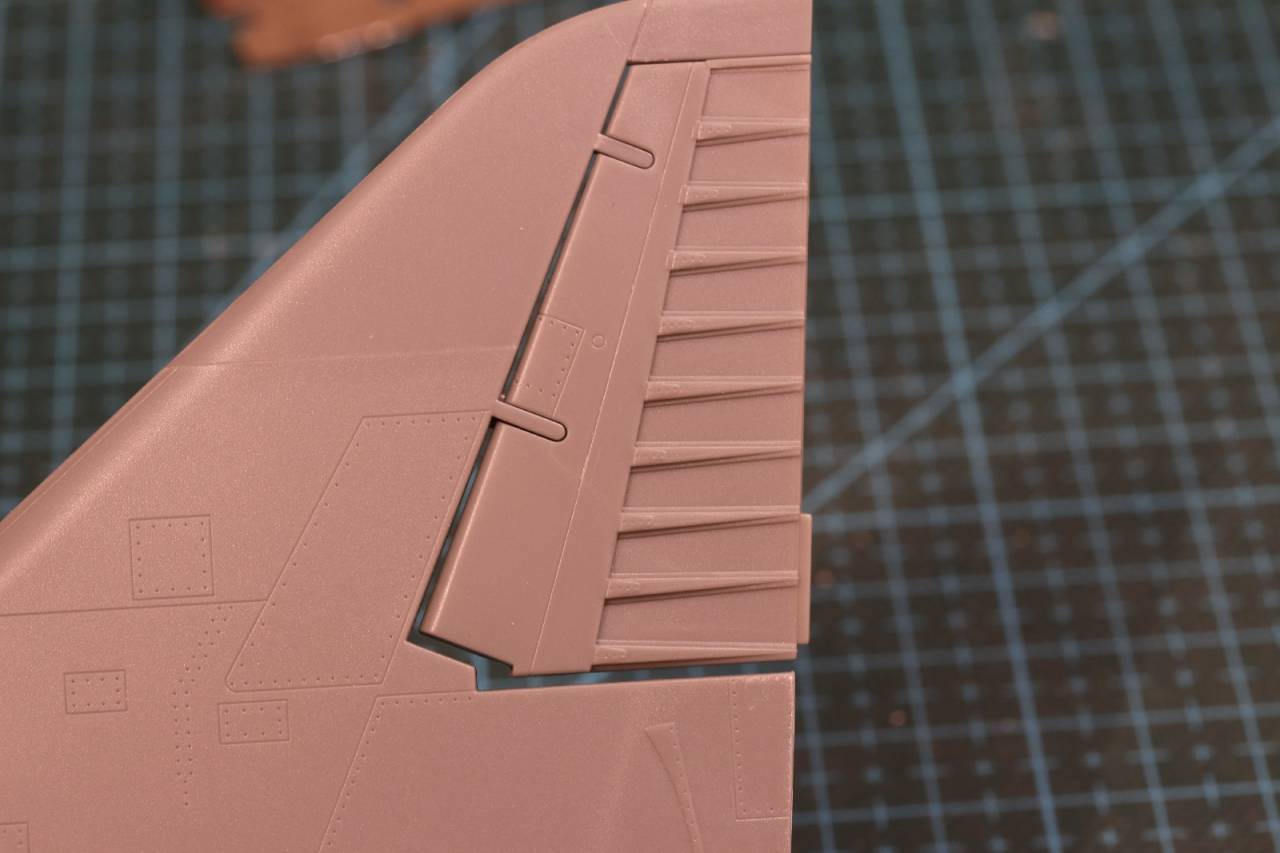

So this is the kit, the A-4E version.

I wasn’t sure how I would depict it though I wanted to do one without the avionics hump but last year with the release of some decal options from AOA for Vietnam Skyhawks I decided on a Marine bird, an A-4C based out of Chu Lai. The squadron is VMA-214, the Blacksheep.

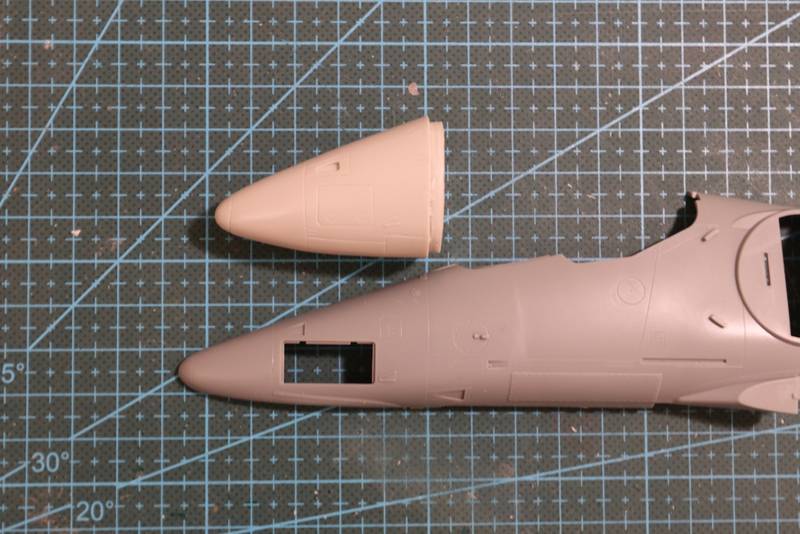

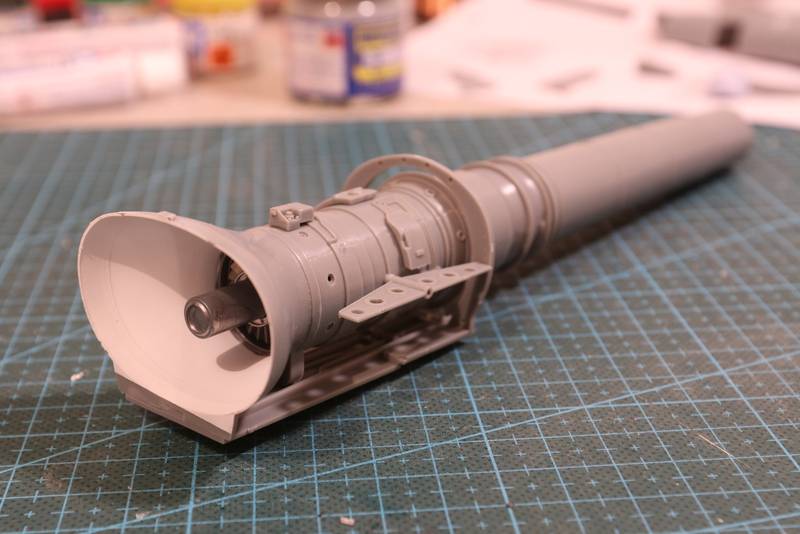

What is great about the AOA offering it also provided a resin set from AMS to provide some key details to backdate the kit from an E to a C Skyhawk. You get a short nose, intakes, a seat, wheels and a windscreen wiper.

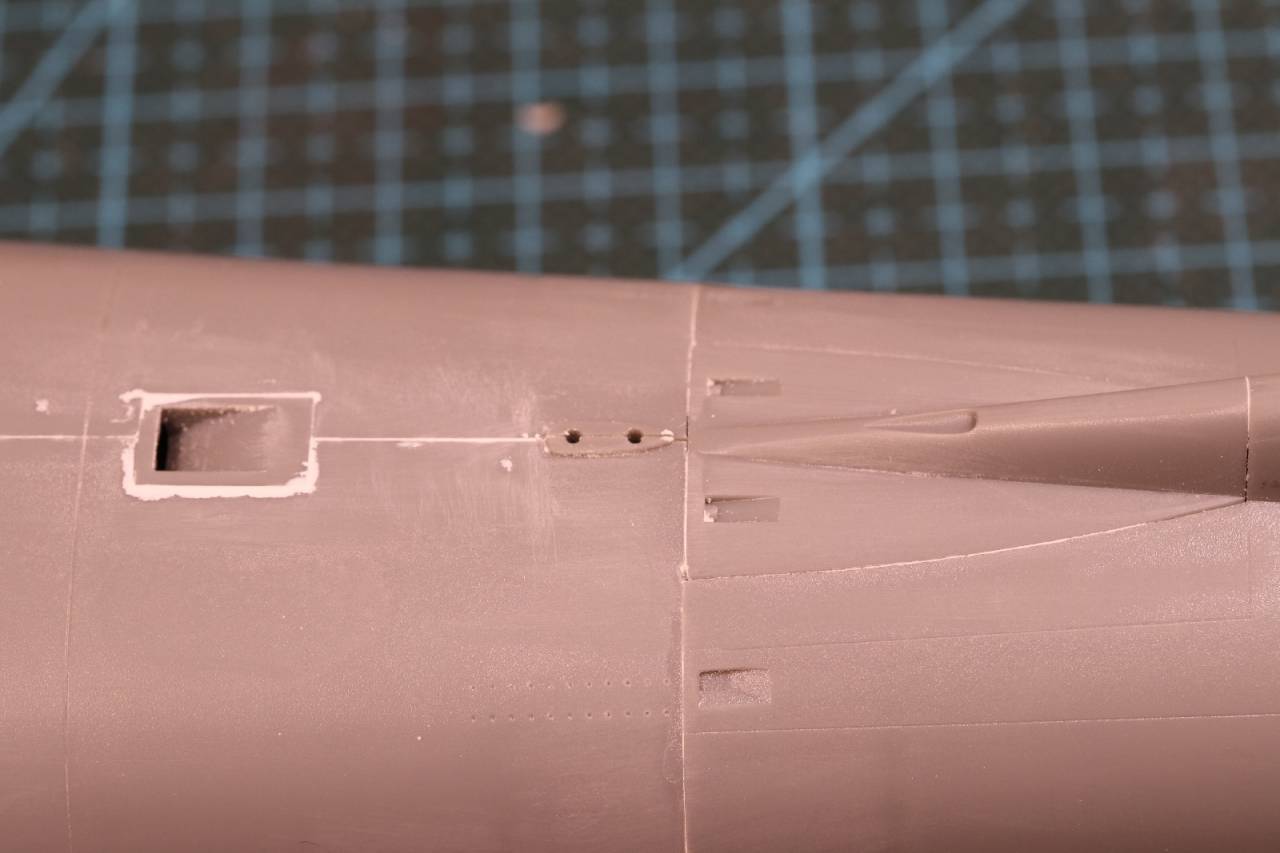

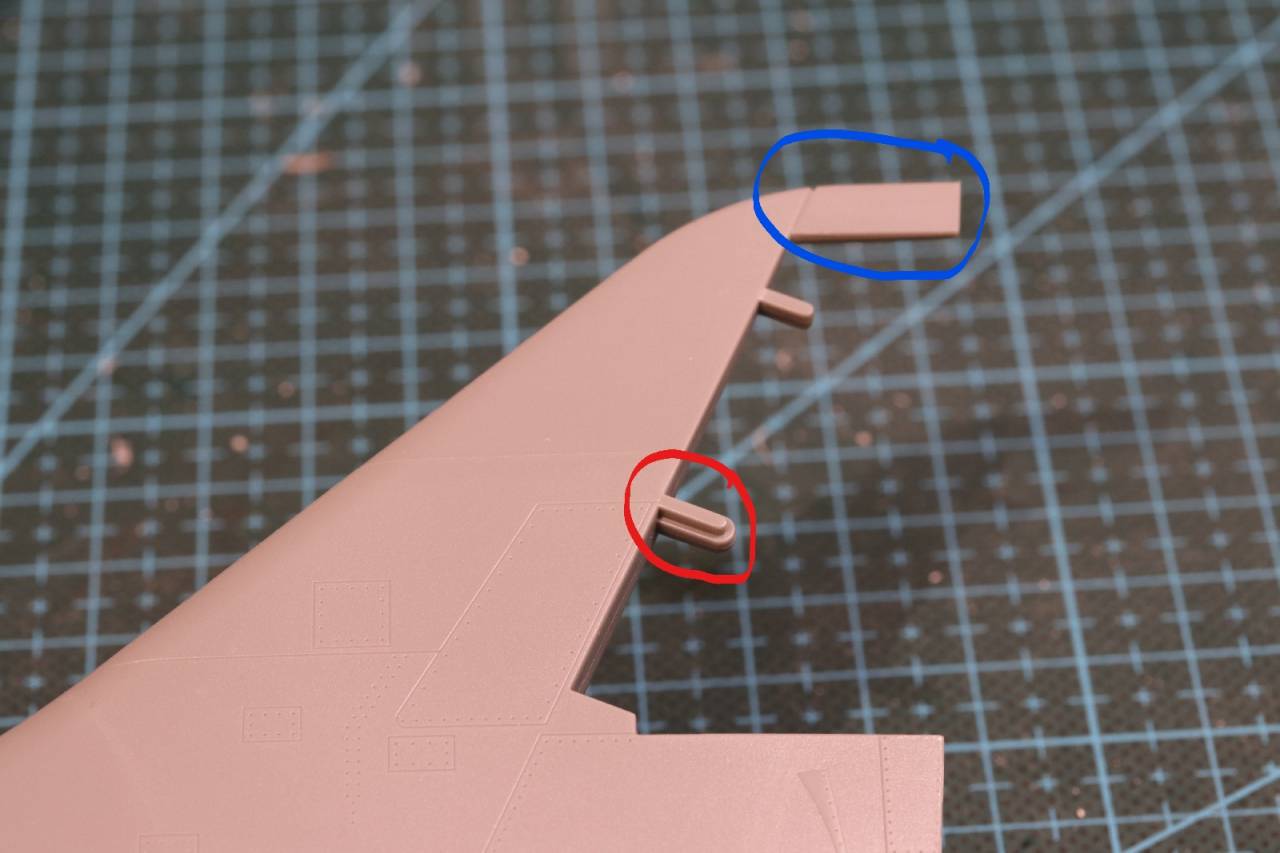

Over the last year I have added some other AM bits to aid with the build and probably most helpfully, the Squadron Walk Around, for the pictures.

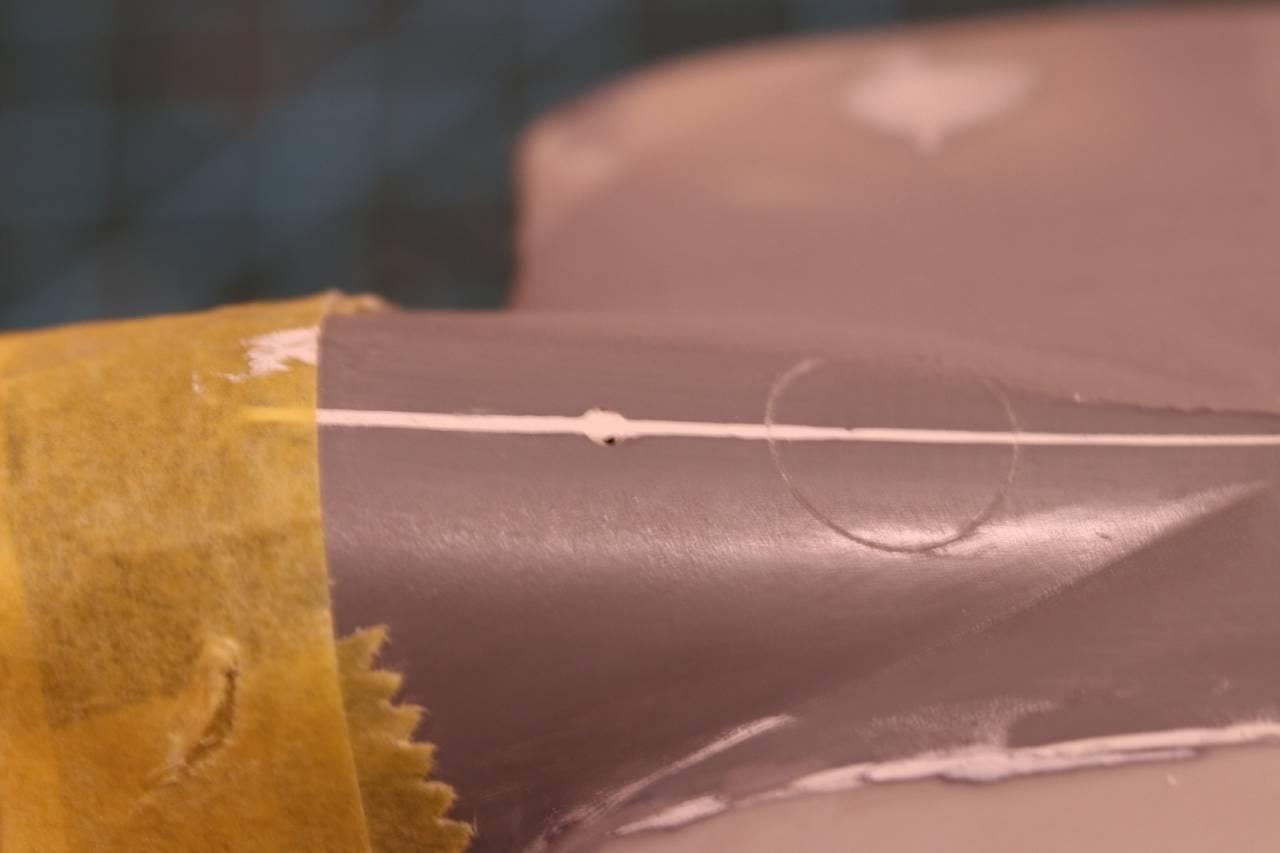

If you have any thoughts about improvements to the base kit feel free to chip in. I am certainly not going for a definitive A-4C but I will do what I can. The AOA information sheet has a number of recommended changes for the conversion and I will start there.

cheers

Michael